Abstract

The faster market changes of EU’s CO2 emission allowance price have increased operation challenges in wood supply of forest industry. The objectives of this study are to present basics of its data-driven modeling for purchasing renewable forest wood. Particularly, the effects of the changes in prices and available carbon sink are considered in management of wood purchasing at the level of the local districts. Two scenarios described procurement situations in non-renewable carbon sinks. The results were compared to the scenario in renewable carbon sink of carbon–neutral forestry. Time-varying emission-allowance parameters of models affected wood purchase and deliveries in the districts. Therefore, cost efficiency of wood-supply operations, as well as the utilization rate of renewable wood resources, can be optimized by data-driven dynamic wood-flow models in digitalized decision support. In addition, the results testify that the model optimizes wood purchasing in the districts at the way of CO2 emission allowance market. Therefore, by using the model wood-supply operations could be optimized toward carbon neutrality, which is important success factor of forest industry.

Similar content being viewed by others

1 Introduction

1.1 Strategic management on scenario basis of carbon neutrality

The EU’s climate and energy regulations drive forest industry to reduce GHG emissions. The EU aims to achieve an overall 80% reduction in emissions by 2050. To reach this long-term target cost-efficiently EU’s domestic emissions are reduced 40 and 60% by 2030 and 2040, respectively (European Commission 2011). In Finland, the forest industry is the most important industrial sector in terms of export revenue and its aim is to achieve carbon neutrality by 2035 (Finnish Forest Industries 2020). Fortunately, the sustainable annual forest growth as wood accumulation amount is higher than realized wood harvesting per year, which enable environmentally sustainable carbon–neutral forestry and wood-supply operations. Therefore, the forest industry will concretely reduce fossil GHG emissions in its operations by tens of percentages for generated energy and produced products by 2030, compared to a 2010 baseline. However, available wood-resource amounts in relation to amounts of potential renewable carbon sink are different in local regions in southeastern Finland.

Palander et al. (2021) concluded that the Finnish forest sector is changing a lot during this decade. It is also suggested that sustainable bioeconomy is developing with support of smart digital investments (Scarlat et al. 2015), which will support integration of the forestry and forest industry. In practice, new investments in carbon–neutral and more sustainable production processes may positively affect the demand and supply of renewable wood (Ministry of Agriculture and Forestry 2015; Ministry of Transport and Communications 2019). If investment really are smart applications, wood harvesting of forests made by the industry also increases viability of carbon sink both in Finnish forests and globally (Thollander and Ottosson 2008; Johansson and Thollander 2018; Palander et al. 2018). In this respect, the ultimate policy of the Finnish government is to meet its renewable energy targets by using forest fuels and create digital advantage for environmentally friendly businesses and society (The Ministry of Economic Affairs and Employment 2017; The Ministry of the Environment 2014).

Management of wood supply chain (WSC) has conventionally been studied and developed in the industry corporations' own wood-supply organizations (Palander 1998; Haavikko et al. 2019). However, there are also small and medium-size companies that supply wood to forest and energy industries. A recent study has justified that efficiency criteria of WSCs are important success factors also to them (Palander and Takkinen 2021). Their role as WSC organizations have been important in energy industry, but currently role is also increasing in the integrated material and energy industry (IMEI), because increasing use of renewable wood combines the chemical, the mechanical, and the energy industry. The WSC can be described as the sub-processes that are inventorying, purchase, harvesting and transport (incl. roadside chipping). Three latter sub-processes have been outsourced to suppliers, because their internal business costs are lower than the costs of the own procurement organization (Palander et al. 2012).

The WSC is coordinated by strategic criteria. Accordingly, the WSC is profitable and socially acceptable, as well as environmentally efficient and ecologically sustainable process (Palander et al. 2020a, b). In WSC logistics the criteria are related to resource optimization. In this respect, the strategic problem can be formulated into the wood-flow model of the procurement process (Fig. 1). Instead of partial optimization the strategic wood-flow model supports global total optimization, in which the solution allocates wood to cost-efficient delivery destinations, and own production facilities are generally the priority. Although huge number of model’s decision variables and constraints don’t cause problems in programming, the complexity of the IMEI makes existing decision support systems (DSSs) insufficient for solving strategic solution alternatives simultaneously in respect to all criteria (Arivalagan et al. 1995; Palander et al. 2018, 2020a).

Since 1990s the DSS has been used in the WSC management. Further, the linear programming (LP) is the basic methodology for minimizing the total costs of the WSCs (Nilsson 1993; Arivalagan et al. 1995; Palander 1998). As the example in Sweden, largely applied optimization tool has been MIND that is also used in the IMEI (Nilsson 1993). More recent studies have focused on the development of smart data-driven applications in system integration of industrial processes (Ghezzaz et al. 2019; Dias and Ierapetritou 2019; Ahmetović et al. 2021). However, the need to develop smart optimization methods also for the WSC cannot be understated, because most small and medium-size companies of the upstream have small financial resources to develop and apply the DSS (Haavikko et al. 2019). For example, if strategic investment decisions of the downstream supply chain affect upstream parts of the IMEI, it may be difficult to approach by an old programming technique and expensive sensitivity analyzes (Gounaris and Grossmann 2019). In addition, fluctuations in energy prices and EU’s emission allowance prices (EEAP) further complicate the DSS development work (Thollander et al. 2009; Fox 2021). In these situations, data-driven modeling of the DSS may be an efficient technique to offer necessary support to the WSC management. It is an innovative technique that can be used to adjust too general LP-models to solution of local situation in the IMEI.

Dias and Ierapetritou (2019) has suggested that need of information can be handled by scenario-based strategic planning. By combining scenario, data-driven modeling, and operational analyses, the DSS can be used to assess the efficiency of strategies in the IMEI. At this work, the data-driven modeling enables optimization of problems that so far have been considered too complex to solve by ordinary computers. Such changing procurement situations of the IMEI may include changes in operating environment, wood-harvesting costs, export/import tariffs, transport costs or wood demands. Recently, consequences from changes in EU’s climate regulations have also been recognized as important issues in operating environment of the IMEI, which needs fast additional answers. In this study, data-driven modelling is experimented with the focus on WSC applications in southeastern Finland.

The management criteria of the WSC have changed in the relatively short period toward minimization of GHG emissions, which can be used to affect carbon neutrality of the WSC. Minimization of CO2 emissions can be made efficient by utilizing the EEAP of the emissions trading markets for emission rights that is assumed to increase over 60 € t−1CO2 (Pöyry 2009). The EEAP has reached on May of 2021 a price level of 44.06 € t−1CO2, which increased over 30% during 2021 (Daily EU ETS carbon market price 2021). It is already known that increase in the EEAP increases WSC costs if fossil fuels are consumed in timber trucks and wood-harvesting machines (Palander and Takkinen 2021). The EEAPs have also an impact on wood purchase costs of the WSC. The scenario work of this study answers to this issue by minimizing an increase in wood purchase costs and calculating decrease or increase in local availability of renewable wood. Generally, to improve carbon neutrality in the WSC, more understanding about sustaining viable carbon sinks of renewable forests is required. Carbon neutrality of the WSCs also means that in local districts of WSC regions the relative difference between the largest sustainable and realized wood-harvesting amounts is positive. In these respects, a calculation procedure of emission-allowance cost parameter may be useful in data-driven wood-flow models, which could be used then as a parameter of the strategic optimization criterion toward minimization of CO2 emissions.

1.2 Objectives of the study

The digital changes in the WSCs, the climate changes, and increased demand of forest wood have increased the challenges for the strategic WSC management. In addition, available wood-resource amounts in renewable carbon sink are different in EU countries and possibly also vary inside single country. Therefore, new data-driven optimization model is formulated for support of the WSC management. The optimization system uses model’s time-varying parameters (Palander 2011a, b) that are designed for the EEAP in wood purchase. They are assumed to be useful contributions to the strategic management. The study describes the management situations using two new scenarios. The changes were primarily analyzed by comparing the effects of the changes on practical supply chains (reference scenario) from the perspective of environmental cost efficiencies. The reference scenario was based on the studies by Hetemäki and Hänninen (2009) which consider effects of EU’s climate warming mitigation policies on forest industry. The results obtained were used to evaluate usefulness of the data-driven optimization at the district level. Specific aims are:

-

To develop data-driven optimization model for considering environmental costs (EEAPs) of wood purchase to retain renewable forest carbon sink and carbon–neutral forest industry.

-

To optimize local wood flows in southeastern Finland by minimizing total WSC costs of the IMEI.

-

To reveal the impact of the EEAP on amounts and costs of wood purchasing in smaller districts of the WSC region.

2 Materials

The research material of 48 districts was collected from the corporation resource planning (CRP) data of an IMEI of Mondi corporation in 2017 and 2018 (Fig. 2). The focus is on the WSCs in southeastern Finland because the IMEI operates on this area and needs information about effects of the EEAP on wood procurement management. This area provides perfect experiment to adjust theoretical general LP-model to solution of local situation of IMEI. The material for the optimization of integrated supply chains is municipal-specific historical WSC-data, which included 14 wood assortments, 21 factories of use, of which 5 factories are using pulpwood, 10 factories are using logs and 6 factories are using energy wood. The WSCs of wood assortments were determined according to the options in Figs. 1 and 2, excluding the possibilities of electricity, fuels, and peat from markets.

Google's map service was used to find out the distances between the districts and the places of factories. The accurate distance data were generated from the most important intersection of roads of the district. The transport costs were calculated by using the cost calculation model, which partly based on the CO2 emission calculations of trucks (Palander et al. 2020a; Haavikko et al. 2022). The EEAP was used for determining these cost parameters. The same model structure was used for calculation of wood-harvesting costs and roadside chipping costs. Actually, the main part of transport costs, wood-harvesting costs and roadside chipping costs were based on corporation’s contract criteria and CRP data. The annual interest rate for operation resources and wood inventories was 4%. Scenario parameters of wood resource balance of districts were determined from the open public forest-balance statistics and the CRP data. Wood purchasing was formulated by using wood assortment-specific pricing. Main databases of the DSS (data mining into Access in Windows) are:

-

Wood resources (from open public forest-balance statistics of districts)

-

Purchase by district and factory (according to the month of the measurement certificate)

-

Cutting and forwarding (from proof of wood harvesting to forest owner)

-

Transport (CRP)

-

Distance matrix (according to actual kilometers and only for distances driven in CRP data)

-

Scenario parameters (from big-data analyses, EEAP, and political regulations)

-

Delivery purchases (wood order—own wood supply)

-

Delivery sales (timber delivery quantities to other companies corresponding factory deliveries + exchanges for pulpwood.

3 Modeling the EEAP for optimization of WSC

This study examines the WSCs of the IMEI from purchase to factories in the logistics upstream, which are also described as wood flows (Fig. 1). Formulation of wood-flow model of the optimization problem was the first task (Model 1). In the recent study by Palander and Takkinen (2021), the model used the environmental efficiency calculation based on fossil and biofuel consumption of trucks and forest machines, which provided an energy-efficient solution in optimization. According to Palander and Takkinen (2021), the objective function of the model takes into account following cost factors of the WSC: purchasing prices, EEAP of fossil fuel consumption, annual interest rates of inventory time, and operation costs. However, increased wood purchase from the non-renewable forest carbon sink increases operations costs, which are not modeled so far.

Purchase operations of districts were optimized for considering sustainable and non-sustainable wood harvesting with varying forest sustainability degree (100, 80 and 60%). Percentage values can be imagined as renewable (100%) and non-renewable (< 100%) forest carbon sinks that are described as scenarios. Further, an effect of the EEAP as environmental costs (30, 50 and 70 € t−1CO2) are added on operative WSC costs. Actually, the EEAP reached on Feb of 2022 a price level of 96.86 € t−1CO2. For this reason, a priory EEAP 70 € t−1CO2 was used in analyses of scenarios. By integrating the sustainability elements of both studies (fuels and carbon sink) in dynamic wood-flow model for periods this programming procedure produces environmentally more efficient WSC solution. Therefore, we describe the mathematical model also in more detail than usual on monthly base for 1 year.

subject to

These constraints of the model describe relationships between the values of environmentally sustainable and non-sustainable wood amounts of forests, as well as available combinations of WSC required at factory at selected time moments.

These constraints are math expressions that describe balances of wood amounts, relationships between the values of WSC variables at selected time moments.

This group of constraints describes wood inventory amounts of stands, roadside and factories at the beginning and end of planning period, as well as variation of them during the same period.

These are non-negativity constraints of the model.

The purpose of optimizing the WSC is to find out the best decision alternative by considering the time-varying costs of the WSC with the minimum total costs. In data-driven modeling of the LP, the dynamic stages of the wood flows and parameters of the model are formulated automatically by customer-oriented programming code. This technique can be used to adjust too general LP-model to solution of local situation in forest industry corporations. Data-driven optimization was done by a C programming code written in house. The program is called PH-Opti that also uses SQL for data-driven modeling and calculation of results. The Simplex optimization method (Dantzig 1961, 1963; Taha 2011) is used for solving the optimization models in the Lindo API sub-program (Lin and Schrage 2009; Lindo API 13.0 2020). This data-driven framework employs a classification code to select cost parameters that are deemed feasible in a scenario as planning problem using historical data and statistics analysis (R Core Team 2020), and the resulting parameters are used in an optimization model of scenario.

4 Scenario analysis

The scenarios based on expected environmental challenges of the national climate warming mitigation as well as to the assessments and policies set at the EU level (Hetemäki and Hänninen 2009; Pöyry 2009; The Ministry of Economic Affairs and Employment 2009). The results of optimization of scenarios B and C were compared to a reference scenario A which is based on district’s available amount of wood resources as a renewable forest carbon sink (Palander and Takkinen 2021). Further, no significant production changes in the industry are expected between the scenarios.

-

(A)

“Extensive energy reform in renewable carbon sink” by Palander and Takkinen (2021).

The total use of forest energy in Finland will increase to the target level of the government achieving 13.5 million m3. The additional need for biorefineries is described in the model as increased wood amounts of energy plants. Therefore, purchasing of wood for energy are assumed to increase by 130%.

-

(B)

B “Declining wood resources of 20% in non-renewable carbon sink” scenario.

Available amount of renewable wood resources is expected to decrease by 20% and the EEAP changes from 30 € t−1CO2 to 70 € t−1CO2.

-

(C)

“Declining wood resources of 40% in non-renewable carbon sink” scenario.

Available amount of renewable wood resources is expected to decrease by 40% and the EEAP changes from 30 € t−1CO2 to 70 € t−1CO2.

5 Results

5.1 Effects of declining available wood resources on WSC

In the scenario C available amount of wood resources of districts declined 40% from levels of renewable carbon sink (Scenario A). Table 1 shows that the total purchasing amounts changed only by 0.6% compared to the reference scenario A (extensive energy reform in renewable carbon sink), but the change of available wood resources caused significant increase in purchasing costs (+ 70.9%) and in relative minimum total costs of the WSC (+ 21.4%). Optimization based on the EEAP of 70 € t−1CO2. Table 1 also shows that the environmental costs are more important in connection of wood purchase than in wood harvesting (+ 2.0%), transport (+ 1.1%) and factory chipping (+ 1.1%). These costs averaged 1.1% on minimum total costs of the WSC.

If available wood resources declined 20% (Scenario B) from a level of renewable carbon sink (Table1), the total purchasing amounts increased by 0.5% compared to the reference scenario A. In the scenario B the change of declining renewable wood resources caused increase in purchasing costs (+ 52.2%) and in relative minimum total costs of the WSC (+ 15.9%). Similarly, as in scenario C, the environmental emission costs, based on the EEAP of 70 € t−1CO2, are more important in connection of wood purchasing than in harvesting (+ 2.0%), transport (+ 1.2%) and factory chipping operations (+ 1.1%), which together are averaged 1.1% of minimum total costs.

5.2 Hot supply chain in renewable forest carbon sink

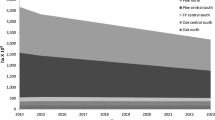

In the scenario A (extensive energy reform in renewable carbon sink), total wood-delivery amount to factories was 677 089 m3. Figure 3 depicts monthly operations of hot supply chain. Wood-harvesting amount was smaller 338 554 m3, because the WSC organizations also buy and sell wood using direct delivery markets. These deliveries happen to roadside-, terminal- or to factory inventories. Therefore, they did not appear as wood-harvesting results of the hot supply chain. Largest operation amounts of the WSC happened in January, because partners’ deliveries were firstly made for hot supply chain. Production and factory inventories increased and stand- and roadside inventories decreased in wood flow, i.e., optimization achieved simultaneously faster lead time and better cost efficiency (less capital).

Monthly wood-supply operations and inventories in the scenario A (extensive energy reform in renewable carbon sink). S is stand inventory, X is roadside inventory, M is factory inventory, P is wood purchasing, L is wood harvesting, Y is roundwood transport, YH is roadside chipping and transport, MH is factory chipping

In Finland, road transport is difficult on spring and new wood inventories are allowed only few weeks on summer, which also fluctuate a lot in local districts. Further, factories are maintained in July that is also most popular holiday period. Therefore, during months of May, June, July, August, and September supply chains fluctuated a lot, but model’s dynamics and balancing equations produced the steady state of the WSC at end of year. Factory chipping was used most during summer, because old wood in factory inventories needed to be circulated. This operation also caused fluctuation in wood purchasing and transport for balancing factory inventorying.

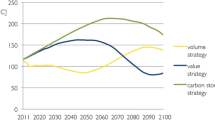

5.3 Purchasing of wood with costs caused by EU’s CO2 emission allowance price

Purchase costs increased a lot if non-renewable wood resources were purchased, because the CO2 emission allowance price was also formulated as model’s additional cost parameter. The scenarios B and C didn’t affect average purchase amounts of the WSCs at wood procurement region level (Table 1) because factories’ wood demands constrained the feasible solutions of the LP-model. In the change by the cost efficiency, the largest decrease was in the Scenario C, as the emission allowance price (70 € t−1CO2) was used in the time-varying cost parameters of the data-driven models. During months of February, March, April, and May purchasing amounts of wood were largest from the non-renewable carbon sink with costs caused by EU’s CO2 emission allowance price. This is environmentally most efficient solution and supply chains are also cost efficient because the total costs are minimized by the model.

5.4 Operations dynamics at district level

As Table 1 shows, the scenarios didn’t affect purchase amounts in the WSCs at wood-supply region level, but the data-driven optimization model and program solved purchase amounts differently at the district level (Fig. 5). For example, renewable energy wood (spruce rotted wood) was purchased evenly, 550 m3 per every month, in district 15 in Scenario A. Differently, in Scenario C, during months of February, March, April and November non-renewable wood were purchased. Further, during January both renewable wood (440 m3) and non-renewable wood (110 m3) were purchased. In Finland, we must use legally “spruce rotted wood” instead of pulp wood as energy wood because pulp wood is purposed and used in pulp production.

As the additional analysis wood transport comparison was applied (Table 2). The energy plant 1 was the only destination where energy wood was delivered from district 15 in Scenario A. The comparison to Scenario C shows that the decrease of 40% from the level of renewable carbon sink together with the emission allowance price of 70 € t−1CO2 affected transport allocation of energy wood. In this situation wood transport was implemented to the energy plants 1 and 21.

Finally, dynamics of supply chains of residual whole wood (an energy-wood assortment) were analyzed in the district 12. Table 3 shows changing scheduling of energy-wood purchase, roadside chipping, and transport. Between the Scenarios A and C monthly purchase amounts changed a lot. For example, in comparison between the Scenarios, during January the purchase amount declined as others only changed. The changes also happened in delivery amounts of forest chips to the energy plants 2 and 5.

6 Discussion

Several useful optimization models have been developed for industry for solving challenges of climate warming mitigation. However, data-driven optimization modeling is seldom considered for wood-purchase planning of the IMEI that affects vitality of the forest carbon sink. The framework of data-driven modeling employed statistical classification methods which are ordinary easy tools to constrain the feasible region of the optimization problem. In several studies also more sophisticated methods are discussed as DSSs for integrated supply-chains (Ahmetović et al. 2021; Dias and Ierapetritou 2019; Gounaris and Grossmann 2019). This data-driven model was assumed to be useful for comparison of alternative supply chains from the perspective of environmental cost efficiencies (Model 1). The results show that the approach was useful contribution to the strategic management of the WSC. The model can be used in the optimal allocation of wood purchasing at the district level. This is important because available wood-resource amounts in relation to amounts of potential renewable carbon sink are different in local regions in southeastern Finland. This model structure can also be used abroad in EU countries for supporting development toward carbon neutrality. These suggestions will be discussed thoroughly in this section.

To optimize wood flows plausibly, it is necessary to minimize total WSC costs. In this respect, the data-driven optimization model considers also environmental costs (EEAPs) of wood purchase to retain renewable carbon sink and carbon–neutral industry. For integrating effects of the emission trade markets more effectively and accurately into the DSS, time-varying parameters were designed for wood purchasing by separating the EEAP of non-renewable wood from purchasing costs of renewable wood (Model 1). This is exactly new contribution for the strategic WSC management of the IMEI, because the EEAP of wood purchasing for the model was only formulated and tested during this study. Actually, several studies have tested functionality and reliability of the other parts of the general LP model structure, which have been found to be adequate for the WSCs (Palander 2011a, b; Palander and Takkinen 2021).

The dynamic linear programming solved the cost-efficient solution to the constrained model of reality (reference scenario), which is a global optimal solution of the Simplex algorithm (Dantzig 1963; Taha 2011; Lindo API 13.0 2020). In addition, the effects of the EEAP (70 € t−1CO2) were analyzed by comparing two scenarios to the reference scenario. In these comparisons, “the hot supply chain in renewable forest carbon sink” was used as the reference scenario because changes of WSC operations depended directly the sequential dynamics of the wood flow from forest to factories (Figs. 1 and 3). By this way the effects of the changes on the environmental cost efficiency can be considered from the perspective of decrease in local available wood resources in the forest carbon sink. In scenarios B and C available renewable wood resources were expected to decrease by 20% and 40%, respectively. In both scenarios no remarkable changes had been expected in the production and practice of the IMEI. Therefore, the focus was on declining wood resources. More precise analysis about effects of varying EEAP will be made in next studies.

The scenarios B and C didn’t affect average amounts of wood purchasing at the wood-supply region level (Fig. 2 and Table 1), but purchase costs increased a lot (52.2 and 70.9%, respectively) if non-renewable wood resources were purchased. Therefore, the EEAP affected the purchasing costs as model’s cost parameter. The total wood-purchase amounts retained quite the same because factories’ wood demands constrained the feasible alternatives of the model. The wood purchasing from the non-renewable carbon sink is made in the first half of the year, because it is environmentally most cost-efficient solution (Fig. 4). It is good to remember that supply chains are also totally cost efficient, although the total costs increased 15.9 and 21.4% respectively, because sum of all cost factors are minimized by the model. Consequently, cost increases are explained largely by the declined supply of renewable wood because the EEAP was used as constant of 70 € t−1CO2 (Thollander et al. 2009; Fox 2021).

Amounts of monthly wood-supply operations and inventories in joined wood flows with EU’s CO2 Emission Allowance Price. Letter S is stand inventory, X is roadside inventory, M is factory inventory, P is wood purchasing in renewable carbon sink, PC is wood purchasing in non-renewable carbon sink with the emission allowance price, L is wood harvesting, Y is roundwood transport, YH is roadside chipping and transport, MH is factory chipping, CP is combined amount of wood purchasing

The sharp fluctuations from May to September in the WSC increased both the capital costs and the minimum total costs. Palander and Takkinen (2021) has explained that expenses increases when inventory turnover slows. Results support their suggestion, roadside inventories increased slightly with minor effect on costs, when factories' chipping increased in June (Fig. 4). In fact, added costs were caused mainly by increased mill inventory. Further, the fluctuations also reflected in purchasing operations. Inside region level, the more specific comparison of renewable and non-renewable carbon sinks revealed that the wood-purchasing operations varied in districts (Fig. 5, Tables 2 and 3). In addition to wood-purchasing amounts, the transport destinations changed in wood flows from districts to energy plants. From these observations it may be suggested that the strategical geographical WSC management is crucial on the way toward carbon neutrality. In this production situation of the IMEI the changes can be considered logical. However, fluctuations in production may increase wood demand of factories more than the DSS can allocate wood purchase to environmentally sustainable districts, which was outside the scope of this study. During the long run the fluctuations may also affect availability of operation resources in wood harvesting and transport. It is worth to mention that the results indicate that wood-supply costs are minor overestimates because steady state of the system may be reached just later during future adjustment periods.

Purchase of energy wood (spruce rotted wood) from district 15. Green line PR depicts purchase amounts in Scenario A (extensive energy reform in renewable carbon sink). P depicts purchase of renewable wood and PC purchase of non-renewable wood in Scenario C (decrease of 40% from a level of renewable carbon sink with the emission allowance price of 70 € t−1CO2

At the time of the study, the sustainable annual forest growth as wood accumulation amount is higher than realized wood harvesting per year, which enable environmentally sustainable carbon–neutral forestry and WSC operations in Finland. Consequently, the emission cost effect is minor in the previous studies and reference scenario (Palander et al. 2020b; Palander and Takkinen 2021). In theory, the data-driven optimization model can be used for strategic scenario analyses, as well as for discussion on results’ effects on the WSC. The results of previous studies justify the theory, which modeled EEAP effects on wood harvesting and transport without accurate consideration of forestry. However, forest growth situation is different at the municipality level, where wood-purchasing amount s at some forest areas still oversite the sustainable growth level, and consequently decrease the renewable carbon sinks. Only two scenarios were designed for our description of declined carbon sinks. This approach may be considered as the plausible for some area at the district level, but as the averages they may be slightly too positive after considering the current variation in Finnish forest structure. In Finland authorities provide national forest databases for IMEI organizations, which were utilized in wood-purchase resource planning. In this advanced public situation data-driven modeling provides successful method and benefits to decision makers, as the precise optimization at the district level is possible. Moreover, because database structures are joined and linked in the program, the same model can be used smartly in DSSs as customer-oriented support to small and middle-size corporations.

7 Conclusions

Data-driven model was developed for the strategic WSC management of the IMEI. Using the proven dynamic linear programming made it possible to efficiently solve the large-scale problem and the solution will scale well to IMEI problems that needs linking environmental data to the objective function. Because software's operating parameters can be easily updated by the user without requiring advanced programming skills, the software lets users adapt the model in response to a changing situation.

Data-driven decision support is necessary for successful strategic management at local district level because the optimization of environmental cost efficiency resulted in changes in local operations of the WSCs. Therefore, amounts of wood purchase in forest carbon sink should, as a rule, be optimized by using the EEAP. When 70 € t−1CO2, and decrease of 40% from a level of renewable carbon sink were used, effects of environmental costs are more important in connection of wood trade (+ 70.9% to purchasing costs, + 21.4% to total costs) than in wood harvesting (+ 2.0% to operation costs, + 1.1% to total costs by using fossil fuel) and transport operations (+ 1.1% to operation costs, + 1.1% to total costs by using fossil fuel). The results obtained show that the environmental costs can be used as a criterion for the environmental sustainability of the IMEI. They are at the same time the success factors on the way to the era of the sustainable bioeconomy.

The industry is subject to EU’s policy regarding emission trading and environmental efficiency regulation. These regulations should be made based on comprehensive scenario analyses of the driving forces for renewable carbon sink by using a WSC model. The wood-purchase optimization illustrated quite well the potential impacts of local forest carbon sinks for forest industry, which is also possible to optimize in a market-oriented manner. However, further studies will be needed to demonstrate the efficiency of the methodology for policy makers in various real-life environments.

Abbreviations

- Z:

-

Minimum WSC costs (€),

- Plmo :

-

Amount (m3) of environmentally sustainable wood l purchased in district m for month o,

- PClmo :

-

Amount (m3) of environmentally non-sustainable wood l purchased in district m for month o,

- Hlmo :

-

Amount (m3) of wood l harvested in district m for month o,

- Tlmno :

-

Amount (m3) of wood l transported from district m to factory n for month o,

- TRlmno :

-

Amount (m3) of wood l transported from district m to factory n for month o,

- MClno :

-

Amount (m3) of wood l chipped at factory n for month o,

- Dlno :

-

Amount (m3) of wood l required at factory n for month o,

- Slmo :

-

Amount (m3) of wood l in stand inventory in district m for month o

- Rlmo :

-

Amount (m3) of wood l in inventory at roadside in district m for month o,

- Mlno :

-

Amount (m3) of wood l in inventory at factory n for month o,

- cplmo :

-

Purchase cost (€m−3) of environmentally sustainable wood l from district m for month o,

- capclmo :

-

CO2 emission allowance cost (€m−3) of environmentally non-sustainable wood l from district m for month o,

- chlmo :

-

Harvesting costs (€m−3) for wood l from district m for month o,

- cahlmo :

-

CO2 emission allowance cost (€m−3) of fossil fuel for harvesting wood l from district m for month o,

- ctlmno :

-

Transport costs (€m−3) of wood l from district m to factory n for month o,

- catlmno :

-

CO2 emission allowance cost (€m−3) of fossil fuel for transport wood l from district m to factory n for month o,

- ctrlmno :

-

Roadside chipping and transport costs (€m−3) of wood l from district m to factory n for month o,

- catrlmno :

-

CO2 emission allowance cost (€m−3) of fossil fuel for roadside chipping and transport wood l from district m to factory n for month o,

- cmclno :

-

Chipping costs (€m−3) of wood l at factory n for month o,

- cmlno :

-

Inventory costs (€m−3) of wood l at factory n for month o,

- Pmaxlmo :

-

Maximum amount (m3) of sustainable harvesting of wood l in district m for month o.

- Dmaxlno :

-

Maximum amount (m3) of wood l required at factory n for month o,

- Dminlno :

-

Minimum amount (m3) of wood l required at factory n for month o,

- Tmaxlm :

-

Maximum amount (m3) of wood l transported from district m,

- Tminlm :

-

Minimum amount (m3) of wood l transported from district m,

- Hmaxlmo :

-

Maximum amount (m3) of wood l harvested from district m for month o,

- Hminlmo :

-

Minimum amount (m3) of wood l harvested from district m for month o,

- Smaxlmo :

-

Maximum amount (m3) of wood l in stand inventory at district m for month o,

- Sminlmo :

-

Minimum amount (m3) of wood l in stand inventory at district m for month o,

- Mmaxlno :

-

Maximum amount (m3) of wood l in inventory at factory n for month o,

- Mminlno :

-

Minimum amount (m3) of wood l in inventory at factory n for month o,

- SIlm :

-

Amount (m3) of wood l in stand inventory at district m at the beginning of year,

- SFlm :

-

Amount (m3) of wood l in stand inventory at district m at the end of year,

- RIlm :

-

Amount (m3) of wood l by roadside in district m at the beginning of year,

- RFlm :

-

Amount (m3) of wood l by roadside in district m at the end of year,

- MIin :

-

Amount (m3) of wood l in inventory at factory n at the beginning of year,

- MFin :

-

Amount (m3) of wood l in inventory at factory n at the end of year,

- ir:

-

Annual interest rate (4%),

- L:

-

Wood assortments (1, …, l, …, 12),

- N:

-

Factories (1, …, n, …, 21),

- O:

-

Months (1, …, o, …, 12)

References

Ahmetović E, Kravanja Z, Ibrić N, Grossmann IE, Savulescu LE (2021) State of the art methods for combined water and energy systems optimisation in Kraft pulp mills. Optim Eng 22:1831–1852. https://doi.org/10.1007/s11081-021-09612-4

Arivalagan A, Raghavendra BG, Rao ARK (1995) Integrated energy optimization model for a cogeneration based energy supply system in the process industry. Elec Powe Energy Sys 17:227–233

Daily EU ETS carbon market price (2021) https://ember-climate.org/data/carbon-price-viewer/. Accessed: 12-April-2021

European Commission (2011) A Roadmap for moving to a competitive low carbon economy in 2050, https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2011:0112:FIN:EN:PDF. Accessed 30-April-2021.

Dantzig GB (1961) On the significance of solving linear programming problems with some integer variables. Econometrica 28:30–44

Dantzig GB (1963) Linear programming and extensions. Princeton University Press, Princeton

Dias LS, Ierapetritou MI (2019) Data-driven feasibility analysis for the integration of planning and scheduling problems. Optim Eng 20:1029–1066. https://doi.org/10.1007/s11081-019-09459-w

Finnish Forest Industries (2020) Green and vibrant economy: The climate roadmap for the forest industry 2035, https://globaluploads.webflow.com/5f44f62ce4d302179b465b3a/5fae9b201811d817517ac8af_Esite_En_Final_V4_Compressed.pdf. Accessed 30-April-2021.

Fox B (2021) EU price on pollution hits record high in early 2021, https://www.euractiv.com/section/emissions-trading-scheme/news/eu-price-on-pollution-hits-record-high-in-early-2021/. Accessed: 30-April-2021.

Ghezzaz H, Bernier E, Savulescu L, Bedard S (2019) Data-driven process modeling and optimization for operation and design improvement: an application for pulp & paper industry. In: foundations of Computer-Aided Process Design (FOCAPD), Copper Mountain Resort Colorado.

Gounaris CE, Grossmann IE (2019) A preface to the special issue on enterprise-wide Optimization. Optim Eng 20:965–968. https://doi.org/10.1007/s11081-019-09468-9

Haavikko H, Kärhä K, Poikela A, Korvenranta M, Palander T (2022) Fuel consumption, greenhouse gas emissions, and energy efficiency of wood-harvesting operations: a case study of Stora Enso in Finland. Croat J for Eng 43. https://doi.org/10.5552/crojfe.2022.1101.10.5552/crojfe.2022.1101

Haavikko H, Kärhä K, Hourula M, Palander T (2019) Attitudes of small and medium-sized enterprises towards energy efficiency in wood procurement: a case study of Stora Enso in Finland. Croat J For Eng 40:107–123. https://hrcak.srce.hr/217401

Hetemäki L, Hänninen R (2009) Outlook for Finland’s Forest Industry Production and Wood Consumption for 2015 and 2020, Working Papers of the Finnish Forest Research Institute, No. 122, https://www.researchgate.net/publication/285856898_Arvio_Suomen_metsateollisuuden_tuotannosta_ja_puunkaytosta_vuosina_2015_ja_2020, [Accessed: 12-April-2021]

Johansson MT, Thollander P (2018) A review of barriers to and driving forces for improved energy efficiency in Swedish industry–Recommendations for successful in-house energy management. Renew Sustain Energy Rev 82:618–628

Lin Y, Schrage L (2009) The global solver in the LINDO API. Optim Methods Softw 24:657–668. https://doi.org/10.1080/10556780902753221

Lindo API 13.0 (2020) Lindo Systems Inc. 1415 North Dayton Street, Chicago, Illinois 60642

Nilsson K (1993) Cost-effective industrial energy systems – multiperiod optimizations of operating strategies and structural choices. Thesis No. 315, Division of Energy Systems, Linköping University, Sweden

Palander T (2011a) Technical and economic analysis of electricity generation from forest, fossil, and wood waste fuels in a Finnish heating plant. Energy 36:5579–5590

Palander T (2011b) Modelling renewable supply chain for electricity generation with forest, fossil, and wood waste fuels. Energy 36:5984–5993

Palander T, Takkinen J (2021) The optimum wood procurement scenario and its dynamic management for integrated energy and material production in carbon-neutral forest industry. Energies 14:4404. https://doi.org/10.3390/en14154404

Palander T, Vainikka M, Yletyinen A (2012) Potential mechanisms for co-operation between transportation entrepreneurs and customers: a case study of regional Entrepreneurship in Finland. Croat J for Eng 33:89–103

Palander T, Haavikko H, Kärhä K (2018) Towards sustainable wood procurement in forest industry—The energy efficiency of larger and heavier vehicles in Finland. Renew Sustain Energy Rev 96:100–118

Palander T, Haavikko H, Kortelainen E, Kärhä K (2020a) Comparison of energy efficiency indicators of road transportation for modeling environmental sustainability in “Green” Circular Industry. Sustainability 12:2740

Palander T, Haavikko H, Kortelainen E, Kärhä K, Borz SA (2020b) Improving environmental and energy efficiency in wood transportation for a carbon-neutral forest industry. Forests 11:1194

Palander T (1998) Tactical models of wood-procurement teams for geographically decentralized group decision making. D.Sc. (Agr. and For.) Thesis. University of Eastern Finland, Finland

Pöyry (2009) Availability of forest bioenergy for energy production in different market situations, https://docplayer.fi/6111313-Energiateollisuus-ry.html, [Accessed: 12-April-2021]

R Core Team (2020) R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. https://www.R-project.org/.

Scarlat N, Dallemand J-F, Monforti-Ferrario F, Nita V (2015) The role of biomass and bioenergy in a future bioeconomy: policies and facts. Environ Dev 15:3–34

Taha HA (2011) Operations Research: An Introduction, 5thedn. Prentice Hall, London.

The Ministry of Agriculture and Forestry (2015) National forest strategy 2025, https://mmm.fi/documents/1410837/1504826/National+Forest+Strategy+2025/197e0aa4-2b6c-426c-b0d0-f8b0f277f332. Accessed: 12-April-2021.

The Ministry of Agriculture and Forestry, The Ministry of the Environment (2014) The Finnish Bioeconomy Strategy, https://biotalous.fi/wp-content/uploads/2014/08/The_Finnish_Bioeconomy_Strategy_110620141.pdf. Accessed: 12-April-2021

The Ministry of Economic Affairs and Employment (2009) Report on the operation of the Finnish wood markets, https://www.researchgate.net/profile/Erkki-Verkasalo/publication/279183864_Comparison_of_alternative_roundwood_pricing_systems_-_A_simulation_approach/links/5603c45108ae460e2704f60a/Comparison-of-alternative-roundwood-pricing-systems-A-simulation-approach.pdf. Accessed: 12-April-2021

The Ministry of Economic Affairs and Employment (2017) Government Report on the National Energy and Climate Strategy for 2030, http://julkaisut.valtioneuvosto.fi/bitstream/handle/10024/79247/TEMjul_12_2017_verkkojulkaisu.pdf. Accessed: 12-April-2021.

The Ministry of the Environment (2020) Annual Climate Report 2020, ISBN:978-952-361-240-2, http://urn.fi/URN:ISBN:978-952-361-240-2. Accessed: 12-April-2021

The Ministry of Transport and Communications (2019) Transport emissions to zero by 2045, https://valtioneuvosto.fi/en/article/-/asset_publisher/liikenteen-paastot-nollaan-vuoteen-2045-mennessa. Accessed: 12-April-2021.

Thollander P, Ottosson M (2008) An energy efficient Swedish pulp and paper industry—exploring barriers to and driving forces for cost-effective energy efficiency investments. Energ Effi 1:21–34

Thollander P, Mardan N, Karlsson M (2009) Optimization as investment decision support tin a Swedish medium-sized iron foundry: a move beyond traditional energy auditing. Appl Energy 86:433–440

Funding

Open access funding provided by University of Eastern Finland (UEF) including Kuopio University Hospital.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visithttp://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Palander, T., Takkinen, J. Data-driven modeling of CO2 emission-allowance compensation for wood-purchasing optimization toward carbon–neutral forest industry. Optim Eng 23, 2091–2110 (2022). https://doi.org/10.1007/s11081-022-09722-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11081-022-09722-7