Trailing Suction Hopper Dredger

Introduction to Trailing Suction Hopper Dredger

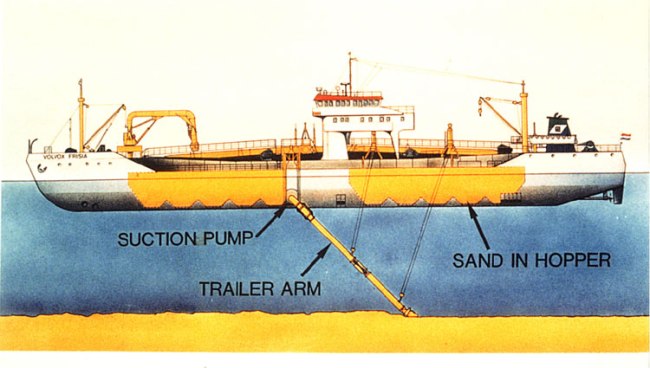

A Trailing Suction Hopper Dredger is a self-propelled ship which fills its hold or hopper during dredging, while following a pre-set track. The hopper can be emptied by opening bottom doors or valves (offloading) or by pumping its load off ashore. This kind of dredger is mainly used in open water: rivers, canals, estuaries and the open sea.

Trailing suction hopper dredgers, commonly known simply as ‘hoppers’ or ‘trailers’, have a hull in the shape of a conventional ship, and are both highly seaworthy and able to operate without any form of mooring or spud. They are equipped with either single or twin (one on each side) trailing suction pipes. Material is lifted through the trailing pipes by one or more pumps and loaded into a hopper contained within the hull of the dredger. The measure of size of a hopper or trailer dredger is the hopper capacity. This may range from a few hundred cubic metres to over 40,000 m³ – increasingly larger vessels have been constructed in recent years to allow economic transport of the dredged material, especially for reclamation projects.

The suction pipe terminates in a drag-head, which may be of the plain type or may incorporate a water jet system, blades or teeth, or other means of dislodging compacted material. The function of the drag-head is to allow the material to flow to the suction inlet as efficiently as possible.

A trailing suction hopper dredger operates very much like a floating vacuum cleaner. It sails slowly over the area to be dredged filling its hopper as it proceeds. On completion of loading the dredger sails to the relocation site where the cargo can be offloaded, either by opening the doors or valves in the hopper bottom, by using the dredging pump to deliver to a shore pipeline, or directly to shore by using a special bow jet. This last technique is known as “rainbowing” and is commonly used for reclamation and beach nourishment.

Some trailer dredgers split over their entire length to achieve a rapid offloading of material which may be difficult to unload through doors. Such special vessels are understandably more expensive to build than those with a rigid hull.

Trailing suction hopper dredgers operate best by skimming off layers of material in long runs, such as might be found in channel dredging. They are unable to get into corners and may be difficult to manoeuvre in confined spaces close to quays and jetties. They are not very effective on hard materials such as the stiffer clays, but can dredge rock which has been blasted, or loosened by a cutter dredger. These dredgers are very efficient for the materials they can handle effectively. Most harbour maintenance dredging today is carried out by trailers, and they are also employed for capital projects, pipe trenching and reclamation.