Camper Van Hydronic Heating System

In our new van we wanted to go for a more robust heating system. We decided on a hydronic heating kit from Rixens Enterprises in Sandy, OR. This all-in-one heating system provides us with hot water, hot air and radiant flooring! Essentially glycol/coolant is heated and pumped through a series of heat exchangers in order to produce heat in the form of water, air, and radiance. In this post I will run through the basics of this system. More info, as well as everything you would need to build a system of your own can be found at Rixens.com. Additionally, the team at Rixens is extremely knowledgeable and very accessible when it comes to customer service and technical support to help you along with your own install.

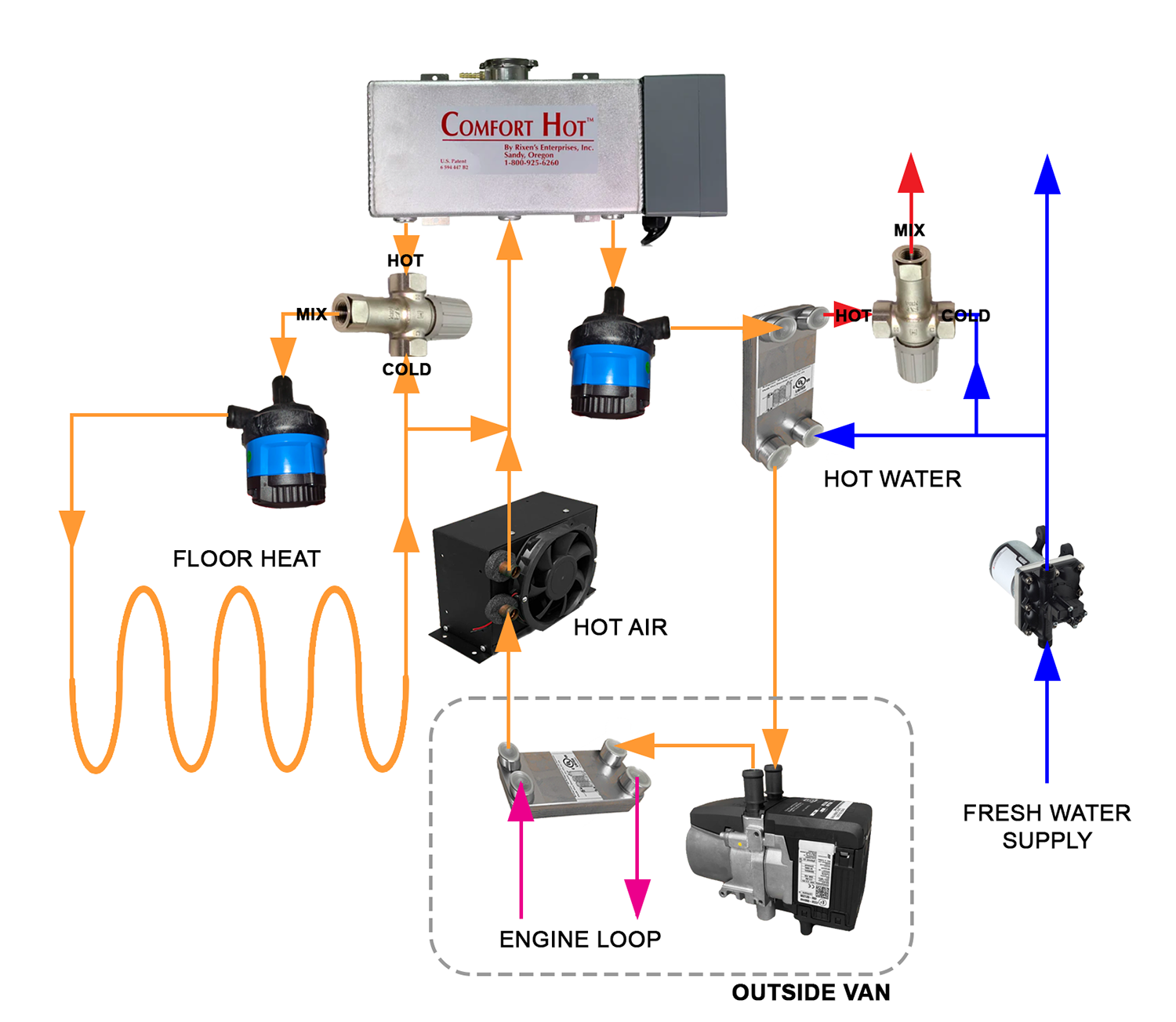

This is the schematic for our hydronic system. It’s based on the info provided by Rixens, although other variations are possible.

Heat Sources

The Furnace

The Eberspacher S3 B5E (Gasoline) Hydronic Furnace is the workhorse of this system. It is a standalone heat source that runs on fuel tapped from the onboard gas tank of our Promaster. (We used this kit to connect to the factory fuel tap located beneath the floormat in between the two front seats.) The provided fuel pump ‘sips’ fuel from the tank to provide what the furnace needs to run when heat is demanded from the system. Although it doesn’t use a whole lot, it’s important to keep an eye on the fuel level as the factory tap only goes down to around ¼ of the tanks capacity. The furnace is mounted on the underside of our van where the combustion intake and exhaust are routed. The kit provides a silencer for the air intake and a muffler for the exhaust. We made sure to keep the intake as far from the exhaust as possible and routed the exhaust vent out to the edge of the van.

Engine Heat

One great advantage of this system (with the Engine Heat Kit) is the ability to use use the heat that is produced from the vehicle itself. Through the use of Rixens’ single-wall heat exchanger mounted beneath the van by the furnace, heat can be sourced via the vans engine coolant when we drive. Not needing to run the furnace for heat means less fuel consumption and less hours on the furnace. It also prevents any road dust/debris from being sucked in through the intake when driving. The heat exchanger, comprised of highly conductive thin copper plates, allows for the separation of the heating system coolant loop and the vehicles engine coolant loop.

The vehicle’s engine coolant loop can be extended to the Rixens heat exchanger just after it leaves the vans heater core. You can find it coming through the firewall in the image below. The 3/4” heater hose can be cut and extended with either straight couplings or elbows in order for the coolant to be sent to the heat exchanger and returned back to the factory loop.

* This diagram is Promaster specific.

Electricity

The last (least efficient) way to heat the glycol/coolant in the system is through the use of electricity. The coolant reservoir we chose came with a 120VAC electrical heating element. Because it pulls around 1500 Watts, we are only able to use it if/when we are plugged into shore power in order to not drain our batteries. The advantage there is less fuel consumption, less hours on our furnace and no exhaust. And without having to run it, we stay dead quiet. I wired the heating element through a dedicated breaker to the ‘AC OUT-2’ on our Victron Multiplus Inverter/Charger. This output of the Multiplus is only energized when an external AC source is supplied.

Applications

Hot Water

The hot water this system provides is produced through a double-wall heat exchanger inside the van. This patented heat exchanger ensures that the coolant and the domestic water can never mix but can be heated with a very high efficiency. Because of this efficiency, the water that comes out is extremely hot. Before the water is supplied to our kitchen faucet and both of our shower mixers, it runs through its own adjustable mixing valve. This takes the cold supply water and the scalding hot water and mixes it to a temperature at the high end of what we would need to call for. When it’s not cold out we still have to remember to heat the system. This is typically only when we’re cooking (washing hands and dishes) or when we want to take a shower. As long as we remember to do that, the hot water is on-demand and essentially endless! To keep the hot water constant, the water flow rate needs to be at around 1 gallon per minute. We accomplished that by adjusting the ball valve on the hot water supply.

Hot Air

In the same fashion that the hot water is produced, Rixens’ air handler uses an internal heat exchanger, but this one with a honeycomb pattern. A large variable speed 12v CPU fan mounted on the backside of the unit pulls air through the heated honeycomb fins. The front of the unit can be fixed either with a flush plate or a flange with many different combinations of vent holes to be ducted to wherever hot air is desired. We mounted our entire heating system in the middle of the van and went with two 3” openings that we ducted to the face of the cabinet in which it’s housed. With the omni-directional and closable vents they provided, we are able to direct hot air to the front and back of the van pretty efficiently.

Radiant Floor

The most attractive and probably most advantageous use of a hydronic heating system is radiant flooring. This part of the system can be added to the main kit as Rixens’ Floor Heat Kit, and it’s actually pretty straight forward. A secondary pump pushes the hot coolant through this dedicated loop of the system through radiant PEX tubing that is routed through the subfloor of the van under the finished flooring. The pump for this loop can be triggered either by a simple on/off switch, or by a dedicated thermostat that is separate from the main thermostat used for the air handler. The floor thermostat should typically be set to around 2 degrees higher than the main thermostat so that the radiant flooring can provide consistent heat, and the fan can kick on whenever the floor can’t keep up with the demand. Our heated floors really provide a nice even consistent heat throughout the van keeping it very cozy.

There are a number of different ways to install the radiant PEX into the subfloor. The decision to add radiant flooring to this van was made after building everything on top of the factory subfloor, so we decided that we could just install it around the cabinetry. We probably wouldn’t recommended installing a heated floor this way, but it was the easiest option for us at that point in the build. We ended up building up some floor cavities and lining the subfloor in ez-cool reflective insulation. Then we used pex bend supports to anchor the pex to the floor and aluminum fins to helps disperse the heat. We screwed those into the floor as well to hold everything down to prevent any rattling, and then covered everything up with 1/2” plywood to accept our finish floor. In hindsight it probably would have been better to have some more insulation below the pex to keep more heat inside the van, and to have the aluminum fins facing upwards to disperse the heat to the finished floor more efficiently. Always learning…

Another method I’ve used to install a radiant subfloor was by laying pex into foam insulation. With 1” XPS ‘pink’ foam and 1” floor joists, I used a handheld plunge router with a template I made to cut out a channel to run the pex throughout the subfloor. Although it was quite the messy process, it was actually not a bad way to go especially if you’re on more of a budget, but still didn’t have enough insulation under the pex to keep the heat from being lost through the bottom of the van. Also could have used some aluminum fins on that one too.

The best option I’ve come across is the Columbia heated subfloor system made by Just Roaming Design. We have yet to install one of these, but will probably be using them going forward.

The system uses a ¾” fiberglass-reinforced closed cell foam that is CNC cut to fit the floor of your van and to house PEX piping and aluminum heat transfer plates. A ¼” overlay is placed on top to provide a smooth surface to accept your finish floor. This overlay is CNC mapped with the positioning of the PEX piping and the aluminum heat transfer plates. The foam substrate is around 60% the weight of plywood. The high density foam works as a sound deadener and will accept traditional fasteners. It is dimensionally stable and will not rot. And most importantly, it provides 3x more insulation than plywood making it a very efficient option for radiant flooring.

Overall we would highly recommend this system to anyone willing to fork out the cash for it. Obviously this system isn’t for everyone as all of our needs differ, but for everything this system handles we’d say its got amazing value!

Also you can check out this Rixens info page and this video for some more in-depth info on the system from Jim Rixen himself!