Tribolium confusum Tribolium castaneum

Tribolium confusum Tribolium castaneum

Tribolium confusum Tribolium castaneum

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

© Stuart M Bennett 2003<br />

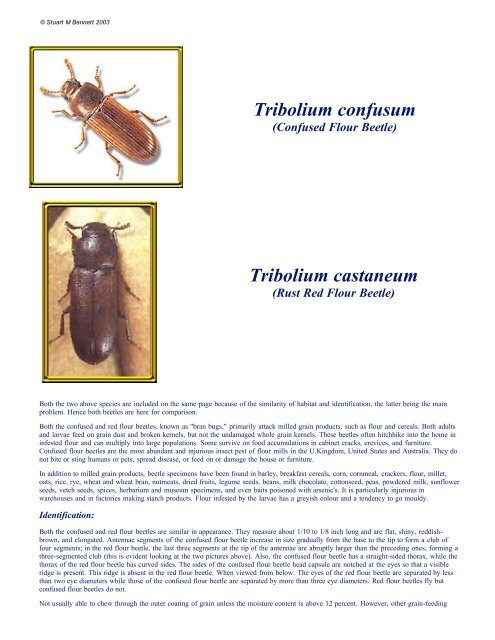

<strong>Tribolium</strong> <strong>confusum</strong><br />

(Confused Flour Beetle)<br />

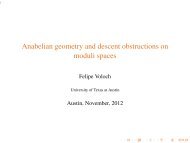

<strong>Tribolium</strong> <strong>castaneum</strong><br />

(Rust Red Flour Beetle)<br />

Both the two above species are included on the same page because of the similarity of habitat and identification, the latter being the main<br />

problem. Hence both beetles are here for comparison.<br />

Both the confused and red flour beetles, known as "bran bugs," primarily attack milled grain products, such as flour and cereals. Both adults<br />

and larvae feed on grain dust and broken kernels, but not the undamaged whole grain kernels. These beetles often hitchhike into the home in<br />

infested flour and can multiply into large populations. Some survive on food accumulations in cabinet cracks, crevices, and furniture.<br />

Confused flour beetles are the most abundant and injurious insect pest of flour mills in the U.Kingdom, United States and Australia. They do<br />

not bite or sting humans or pets, spread disease, or feed on or damage the house or furniture.<br />

In addition to milled grain products, beetle specimens have been found in barley, breakfast cereals, corn, cornmeal, crackers, flour, millet,<br />

oats, rice, rye, wheat and wheat bran, nutmeats, dried fruits, legume seeds, beans, milk chocolate, cottonseed, peas, powdered milk, sunflower<br />

seeds, vetch seeds, spices, herbarium and museum specimens, and even baits poisoned with arsenic's. It is particularly injurious in<br />

warehouses and in factories making starch products. Flour infested by the larvae has a greyish colour and a tendency to go mouldy.<br />

Identification:<br />

Both the confused and red flour beetles are similar in appearance. They measure about 1/10 to 1/8 inch long and are flat, shiny, reddishbrown,<br />

and elongated. Antennae segments of the confused flour beetle increase in size gradually from the base to the tip to form a club of<br />

four segments; in the red flour beetle, the last three segments at the tip of the antennae are abruptly larger than the preceding ones, forming a<br />

three-segmented club (this is evident looking at the two pictures above). Also, the confused flour beetle has a straight-sided thorax, while the<br />

thorax of the red flour beetle has curved sides. The sides of the confused flour beetle head capsule are notched at the eyes so that a visible<br />

ridge is present. This ridge is absent in the red flour beetle. When viewed from below. The eyes of the red flour beetle are separated by less<br />

than two eye diameters while those of the confused flour beetle are separated by more than three eye diameters. Red flour beetles fly but<br />

confused flour beetles do not.<br />

Not usually able to chew through the outer coating of grain unless the moisture content is above 12 percent. However, other grain-feeding

insects and mechanical harvesting injury provide a source of cracked kernels and dust food for them. The adults have glands on the abdomen<br />

and thorax which release a pungent gas when the insects are irritated. This, in turn, may produce a very undesirable odour in the grain.<br />

Contamination also occurs from the accumulation of dead bodies and waste products.<br />

The eggs, larvae, and pupae are similar in both beetles. Eggs are whitish or colourless and microscopic in size, with food particles adhering to<br />

the sticky surface. Brown-headed larvae are cream to yellow, slender, and wiry, reaching a length of 1/4 inch (see picture below of beetles<br />

and larvae in flour). Larvae have six legs and two-pointed or forked projections at the last rear body segment. Pupae are white to light brown.<br />

Life Cycle:<br />

This is a very prolific species. Both beetles breed in damaged grain, grain dust, high-moisture wheat kernels, flour, etc. Female beetles each<br />

lay 300 to 400 eggs in flour or other foods during a period of five to eight months (two to three eggs per day). Within 5 to 12 days, these eggs<br />

hatch into slender, cylindrical, white larvae tinged with yellow. The length of the larval period varies from 22 to more than 100 days; the<br />

pupal period is about 8 days. Fully grown larvae transform to naked pupae, and in a week adults emerge. The life cycle requires 7 to 12<br />

weeks, with adults living for 3 years or more. Ideally this type of beetle prefers temperatures of ca. 30°C and will not develop or breed at<br />

temperatures lower than 18°C.<br />

Treatment:<br />

Usually the most simple and effective control measure is to locate the source of infestation and quickly get rid of it. Dispose of heavily<br />

infested foods in wrapped, heavy plastic bags or in sealed containers and leave for garbage disposal service. If you detect these beetles early,<br />

disposal alone may solve the problem.<br />

Careful sanitation is the best method to avoid any stored-product pests. After removing all food, food packages, utensils, dishes, etc. from the<br />

cupboard, shelves, or storage area, use a strong suction vacuum cleaner with proper attachments to clean all spilled foods (flour,rice, toaster<br />

crumbs, bits of pet food, raisins, etc.) from the cracks and crevices, behind, under, and in appliances and furniture. Scrub with soap and hot<br />

water. After shelves are thoroughly dry, cover with clean, fresh paper or foil before replacing with food (which is free from infestation) or<br />

cooking utensils.<br />

In the case of industrial problems e.g. food factories, grain silos, bulk flour stores etc., as well as carrying out the procedures above, which<br />

should be an on-going task anyway, fumigation may have to be considered. This can be a costly procedure, but if the calculations show that it<br />

is cheaper to fumigate and still be able to use the grain after screening, rather than just throw the whole lot away, which, let's face it, is a<br />

waste, then it could be the way to go.<br />

Managers should be aware of the hidden places which are not always cleaned or serviced such as, hard to get at parts of machinary, if there<br />

are augers in use there could well be a build up in the boxing around the auger itself, in fact any dead space which can be quite easily<br />

forgotten about is a prime target for this type of pest and once they get a hold there is a lot of money involved.<br />

Make sure that your pest controller is doing their job correctly, and not just wandering on site, checking a few rodent boxes and wandering<br />

off site again.<br />

Ideally you may need a consultant like myself to do a half yearly inspection. That way you will get an independant assessment of the site as it<br />

stands at that point in time.<br />

Top<br />

Back to main Stored Product Insect page