Stainless Services in Italy - Outokumpu

Stainless Services in Italy - Outokumpu

Stainless Services in Italy - Outokumpu

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

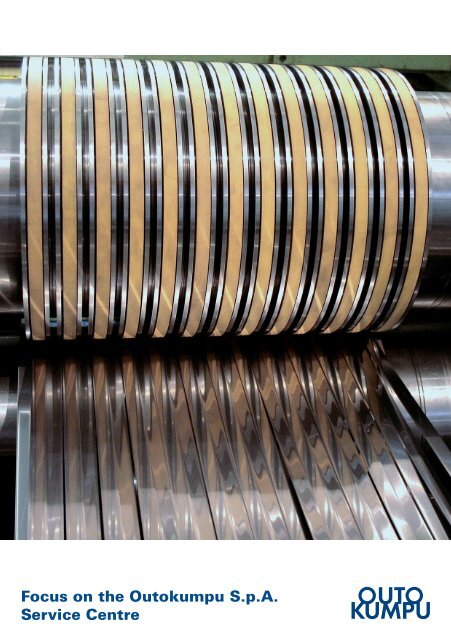

Focus on the <strong>Outokumpu</strong> S.p.A.<br />

Service Centre

Why the <strong>Outokumpu</strong><br />

S.p.A. Service Centre?<br />

A wide range of sta<strong>in</strong>less steels<br />

Intended for general use or <strong>in</strong> specific fields such as the<br />

chemical or petrochemical <strong>in</strong>dustry, food-process<strong>in</strong>g, pulp&paper,<br />

structural, thermal or mechanical applications, ship-build<strong>in</strong>g,<br />

furniture and household appliances.<br />

We can provide the appropriate range of steels for all ord<strong>in</strong>ary<br />

market request, and special grades for any particular demand.

Materials & Quality<br />

Quality level is the key po<strong>in</strong>t for all subsequent operations.<br />

Our plants, technologically advanced, enable us to be considered<br />

as a trustful partner <strong>in</strong> terms of quality.<br />

The materials are produced <strong>in</strong> conformity with the appropriate<br />

standards respect<strong>in</strong>g the regulation related to the<br />

specific f<strong>in</strong>al use.<br />

Complete eng<strong>in</strong>eer<strong>in</strong>g and plant design<br />

solutions<br />

We can arrange solutions to cover the whole range of<br />

products needed by customers. In fact, they can refer to a s<strong>in</strong>gle source<br />

supplier for flat, long, tubular and plasma cutt<strong>in</strong>g products avoid<strong>in</strong>g to<br />

use several different suppliers. In this way we will optimize time research,<br />

time response and transport costs <strong>in</strong> order to economize all purchase<br />

phases.<br />

Fast delivery times<br />

Reliable partner carriers re<strong>in</strong>force our reputation as stable and trustful<br />

supplier.

Flat products: technical specifications of mach<strong>in</strong>es and systems<br />

2000 mm HR / CR coil-levell<strong>in</strong>g mach<strong>in</strong>e<br />

It is one of the most powerful coil leveller and cut-to-lenght l<strong>in</strong>e used <strong>in</strong> service centers. It allows to obta<strong>in</strong> a range of extra long sheets with very<br />

good flatness tolerances, even on the thickest material.<br />

Weight of coil Width<br />

Length of sheets Thickness<br />

30000 kg 700 to 2050 mm 1500 to 13000 mm<br />

HR 3 to 14 mm<br />

CR 4 to 8 mm<br />

2000 mm CR coil-levell<strong>in</strong>g mach<strong>in</strong>e<br />

The mach<strong>in</strong>e is equipped with two levellers facilities and a double stacker performed with a vacuum-operated system which, avoid<strong>in</strong>g mechanical<br />

contacts with the material, ensures a good quality surface.<br />

Weight of coil<br />

30000 kg<br />

Width<br />

900 to 2050 mm<br />

Length of sheets<br />

600 to 800 mm<br />

Thickness<br />

0.5 to 3.0 mm<br />

1500 mm CR coil-levell<strong>in</strong>g and blank<strong>in</strong>g l<strong>in</strong>e<br />

Advanced technology cut-to-length l<strong>in</strong>e for narrow strips cut-to-size. The mach<strong>in</strong>e is equipped with two levellers facilities and a double stacker<br />

performed with a vacuun system which, avoid<strong>in</strong>g mechanical contacts with the material, ensures a good quality surface.<br />

Weight of coil<br />

30000 kg<br />

Width<br />

200 to 350 mm<br />

350 to 1550 mm<br />

Length of sheets<br />

350 to 3000 mm<br />

350 to 6000 mm<br />

Thickness<br />

0.4 to 3.0 mm

1500 mm CR coil slitter<br />

This longitud<strong>in</strong>al slitt<strong>in</strong>g l<strong>in</strong>e enables to obta<strong>in</strong> narrow coils with tight tolerances.<br />

Weight of<br />

coil<br />

Width of<br />

coil<br />

(<strong>in</strong>go<strong>in</strong>g)<br />

Outside dia.<br />

of coil<br />

Inside dia. of<br />

coil<br />

(outgo<strong>in</strong>g)<br />

Thicknesses<br />

M<strong>in</strong>. width<br />

obta<strong>in</strong>able<br />

30000 kg from 100 to 1540 mm 2000 mm 500 mm from 0.4 to 1.5 mm 20 mm<br />

from 2 to 3 mm 25 mm<br />

1000mm HR/CR coil slitter<br />

This is a dedicated mach<strong>in</strong>e for process<strong>in</strong>g HR coils with thicknesses of up to 6 mm. Longitud<strong>in</strong>al slitt<strong>in</strong>g l<strong>in</strong>e used to process coil with thicknesses<br />

up to 6 mm.<br />

Weight of<br />

coil<br />

Width of<br />

coil<br />

(<strong>in</strong>go<strong>in</strong>g)<br />

Outside dia.<br />

of coil<br />

Inside dia. of<br />

coil<br />

(outgo<strong>in</strong>g)<br />

20000 kg from 150 to 1040 mm 2000 mm 500 mm<br />

Thicknesses<br />

from 0.5 to 1.5 mm<br />

from >1.5 to 3.0 mm<br />

from >3.0 to 6.0 mm<br />

M<strong>in</strong>. width<br />

obta<strong>in</strong>able<br />

12 mm<br />

25 mm<br />

30 mm

Flat products: technical specifications of mach<strong>in</strong>es and systems<br />

Polish<strong>in</strong>g l<strong>in</strong>e for 2000 mm HR / CR sheets<br />

This world class four cab<strong>in</strong>s l<strong>in</strong>e works with gr<strong>in</strong>d<strong>in</strong>g belts that guarantee a constitent roughness all over the sheet surface, on both sides. Sheets can be<br />

also protected with plastic film (<strong>in</strong> accordance with market standards).<br />

Width of sheets<br />

800 to 2000 mm<br />

Length of sheets<br />

2000 to 12000 mm<br />

Thickness<br />

3 to 14 mm<br />

or thicker on sheets made from flat blooms<br />

Polish<strong>in</strong>g l<strong>in</strong>e for 1600 mm CR sheets<br />

This mach<strong>in</strong>e is very recently made and is equipped with state-of-the-art technical arrangements.<br />

It works with three polish<strong>in</strong>g /cab<strong>in</strong>s.<br />

Sheets can be also protected with plastic film (<strong>in</strong> accordance with market standards).<br />

Width of sheets<br />

700 to 16000 mm<br />

Length of sheets<br />

900 to 6000 mm<br />

Thickness<br />

0.6 to 4 mm

Coil to coil polish<strong>in</strong>g l<strong>in</strong>es H 2000 mm<br />

Our service center is fitted with two polish<strong>in</strong>g l<strong>in</strong>es coil to coil, equipped with three polish<strong>in</strong>g cab<strong>in</strong>s, technologically advanced, enabl<strong>in</strong>g a high<br />

perform<strong>in</strong>g production capability, which guarantees the most accurate quality requirements.<br />

Our cont<strong>in</strong>uos research and <strong>in</strong>novation process, has lead us - <strong>in</strong> relationship with our partners and suppliers - to develop a wide range<br />

of surface f<strong>in</strong>ishes so to satisfy the most demand<strong>in</strong>g customers.<br />

In addition to the standard dry f<strong>in</strong>ishes (from gra<strong>in</strong> 80, up to gra<strong>in</strong> 400), Duplo f<strong>in</strong>ish<strong>in</strong>g and Taylor made f<strong>in</strong>ishes, we have developed a scotch brite<br />

f<strong>in</strong>ish<strong>in</strong>g carried out with special cork belts, represent<strong>in</strong>g nowadays the highest standard on the market both <strong>in</strong> terms of quality and production<br />

results.<br />

Weight of coil<br />

30000 kg<br />

Inside diameter (outgo<strong>in</strong>g)<br />

500 and 600 mm<br />

Width of Coils for polish<strong>in</strong>g<br />

Thickness<br />

600 ÷ 900 mm<br />

≥ 0.8 ≥ 0.8 mm mm<br />

Polish<strong>in</strong>g<br />

> 900 ÷ 2000 mm<br />

0.5 0.5 ÷ 3 ÷ mm 3 mm<br />

Scotch Brite 900 ÷ 2000 mm 0.5 0.5 ÷ 3 ÷ mm 3 mm

Cutt<strong>in</strong>g systems<br />

Plasma cutt<strong>in</strong>g<br />

Plasma cutt<strong>in</strong>g<br />

Submerged cutt<strong>in</strong>g ensures less taper<strong>in</strong>g of the cutt<strong>in</strong>g edge, a reduction of<br />

the heat affected zone and a better work<strong>in</strong>g environment, with no fumes,<br />

noise or dispersion of UV light.<br />

Band-saw<strong>in</strong>g mach<strong>in</strong>e<br />

Band-saw<strong>in</strong>g mach<strong>in</strong>e<br />

High-precision mechanical cutt<strong>in</strong>g with 90° angles.<br />

1 submerged-cutt<strong>in</strong>g system<br />

(maximum Quarto Plate lenght <strong>in</strong> entrance: 15000 mm)<br />

2 cutt<strong>in</strong>g tables, 3200x7500 mm<br />

Maximum thickness: 60 mm<br />

2 band-saw<strong>in</strong>g mach<strong>in</strong>e<br />

Length: 6250 mm<br />

Width: 2000 mm<br />

Thickness: 300 mm<br />

1 submerged-cutt<strong>in</strong>g system<br />

(maximum Quarto Plate lenght <strong>in</strong> entrance: 15000 mm)<br />

2 cutt<strong>in</strong>g tables, 3200x6500 mm<br />

Maximum thickness: 40 mm (submerged cut)<br />

Maximum thickness: 120 mm (dry cut)<br />

1 band-saw<strong>in</strong>g mach<strong>in</strong>e<br />

Width: 520 mm<br />

Thickness: 520 mm<br />

1 band-saw<strong>in</strong>g mach<strong>in</strong>e<br />

Length: 1200 mm<br />

Thickness: 300 mm

Range of qualities and thicknesses available for cutt<strong>in</strong>g<br />

Range of qualities and thicknesses available for cutt<strong>in</strong>g<br />

Standard grades<br />

EN 1.4301 / 4307 - 304/L<br />

EN 1.4307 - 304L Prodec<br />

EN 1.4401 / 4404 - 316/L<br />

EN 1.4404 - 316L Prodec<br />

EN 1.4541 - 321<br />

EN 1.4571 - 316Ti<br />

Thicknesses<br />

3 - 100 mm<br />

15 - 50 mm<br />

3 - 100 mm<br />

15 - 80 mm<br />

3 - 60 mm<br />

3 - 50 mm<br />

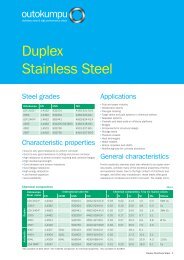

Duplex grades<br />

EN 1.4162 - LDX 2101®<br />

EN 1.4362 - 2304<br />

EN 1.4662 - LDX 2404<br />

EN 1.4462 - 2205<br />

EN 1.4410 - 2507<br />

Special grades<br />

EN 1.4539 - 904L<br />

EN 1.4547 - 254 SMO ®<br />

EN 1.4529<br />

EN 1.4835 - 253 MA ®<br />

Thicknesses<br />

3 - 40 mm<br />

3 - 40 mm<br />

3 - 40 mm<br />

3 - 100 mm<br />

3 - 50 mm<br />

Thicknesses<br />

3 - 50 mm<br />

3 - 15 mm<br />

20 - 50 mm<br />

3 - 40 mm

Tubular products and fitt<strong>in</strong>gs<br />

Round pipes<br />

Seamless<br />

Hot or cold f<strong>in</strong>ished <strong>in</strong> accordance with ASTM A213 -<br />

A268 - A269 - A271 - A312 - A376 - A789 - A790 and with<br />

European EN standards.<br />

TIG welded – for pressure purposes<br />

Welded <strong>in</strong> accordance with standard requirements us<strong>in</strong>g<br />

the automatic or semi-automatic weld<strong>in</strong>g TIG or TIG +<br />

plasma process; natural external or <strong>in</strong>ternal bead or rolled<br />

<strong>in</strong>ternally, flat or bevelled ends; solubilised and pickled or<br />

solubilised <strong>in</strong> a neutral atmosphere.<br />

The material <strong>in</strong> stock complies with the standards <strong>in</strong> terms of technical<br />

requirements, test<strong>in</strong>g standards and mark<strong>in</strong>gs.<br />

Round, square and rectangular tubes<br />

TIG or LASER welded – for general use<br />

Welded automatically us<strong>in</strong>g the TIG process, natural<br />

external or <strong>in</strong>ternal bead; not solubilised; no eddy-current<br />

control. External f<strong>in</strong>ish<strong>in</strong>g of the strips used brushed or<br />

polished. Certified accord<strong>in</strong>g to EN 10204. Not suitable<br />

for pressure purposes.<br />

HF welded – for construction and ornamental<br />

use<br />

Welded us<strong>in</strong>g the high-frequency process.<br />

natural external or <strong>in</strong>ternal bead or removal of <strong>in</strong>ternal bead;<br />

not solubilised, no eddy-current control. External f<strong>in</strong>ish of<br />

the strips used brushed or polished. Certified accord<strong>in</strong>g to<br />

EN 10204. Not suitable for pressure purposes.<br />

Standards<br />

EN10216-5 for seamless sta<strong>in</strong>less steel tubes.<br />

EN 10217-7 for welded pipes for pressure purposes.<br />

EN 10296-2 for TIG or Laser welded pipes, not annealed, for<br />

general use, and HE welded pipes<br />

For ornamental or construction use<br />

EN 10204 for <strong>in</strong>spection documents.<br />

PED 97/23/EC for equipment for pressure purposes.

Square and rectangular hollow sections<br />

Hot rolled round bars – peeled<br />

AISI 303 - 304L - 316L<br />

Rolled square bars<br />

AISI 303 - 304L - 316L<br />

tolerance ISO H11<br />

Ø mm<br />

from: 20 to: 200<br />

Size mm<br />

from: 8 to: 22<br />

Cold drawn round bars tolerance ISO H9<br />

AISI 303 - 304 - 304L - 316L<br />

Ø mm<br />

from: 3 to: 70<br />

Sheared flat bars<br />

AISI 304L - 316L<br />

from: 10x3<br />

Size mm<br />

to: 200x8<br />

Rolled centerless ground bars tolerance ISO H8<br />

AISI 303 - 304L - 316L<br />

Size mm<br />

from: 5 to: 25<br />

Equal-sided angle bars<br />

AISI 304L - 316L<br />

from: 20x20x3<br />

Size mm<br />

to: 100x100x10<br />

Cold drawn exagonal bars tolerance ISO H11<br />

AISI 303 - 304L - 316L<br />

Ø mm<br />

from: 6 to: 25

<strong>Outokumpu</strong>'s additional services<br />

Certificates<br />

Test<strong>in</strong>g (DNV - BUREAU VERITAS - LLOYD’S REGISTER -<br />

RINA)<br />

Chemical test<strong>in</strong>g<br />

Mechanical specifications<br />

Dimensional checks<br />

PMI (Positive Material Identification)<br />

Non-destructive test<strong>in</strong>g (penetrant – X-ray and US <strong>in</strong>spection)<br />

Corrosion test<strong>in</strong>g<br />

Test certificates<br />

Cutt<strong>in</strong>g to size<br />

Chamfers<br />

Polish<strong>in</strong>g – mirror polish<strong>in</strong>g<br />

Mark<strong>in</strong>gs<br />

Protective sheaths<br />

Plugs<br />

Packag<strong>in</strong>g to specifications

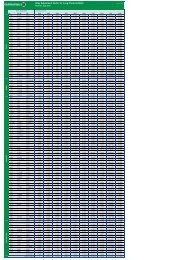

Chemical composition of the sta<strong>in</strong>less<br />

steels available from the Service Centre<br />

Ferritic<br />

Duplex<br />

International<br />

International<br />

designation<br />

designation OUTOKUMPU Typical chemical composition, OUTOKUMPU Typical chemical composition, %<br />

designation<br />

designation<br />

EN<br />

EN<br />

ASTM/UNS<br />

ASTM/UNS C N<br />

Cr<br />

Cr<br />

Ni<br />

Ni<br />

Mo<br />

Mo<br />

Other<br />

Other<br />

1.4512<br />

1.4512<br />

409<br />

409<br />

4512<br />

4512<br />

0.02<br />

0.02 -<br />

11.5<br />

11.5 - -<br />

0.2Ti<br />

0.2Ti<br />

1.4016<br />

1.4016<br />

430<br />

430<br />

4016<br />

4016<br />

0.04<br />

0.04 -<br />

16.5<br />

16.5 - - -<br />

1.4509<br />

1.4509<br />

S43932<br />

S43932<br />

4509<br />

4509<br />

0.02<br />

0.02 -<br />

18<br />

18 - -<br />

NbTi<br />

NbTi<br />

1.4521<br />

1.4521<br />

444<br />

444<br />

4521<br />

4521<br />

0.02<br />

0.02<br />

0.01<br />

0.01<br />

17.8<br />

17.8 -<br />

2.1<br />

2.1<br />

Ti<br />

Ti<br />

1.4162<br />

1.4162<br />

S32101<br />

S32101<br />

LDX<br />

LDX<br />

2101<br />

2101<br />

0.03<br />

0.03<br />

0.22<br />

0.22<br />

21.5<br />

21.5<br />

1.5<br />

1.5<br />

0.3<br />

0.3<br />

5Mn<br />

5Mn<br />

1.4362<br />

1.4362<br />

S32304<br />

S32304<br />

2304<br />

2304<br />

0.02<br />

0.02<br />

0.10<br />

0.10<br />

23<br />

23<br />

4.8<br />

4.8<br />

0.3<br />

0.3 -<br />

1.4462<br />

1.4462<br />

S32205<br />

S32205<br />

2205<br />

2205<br />

0.02<br />

0.02<br />

0.17<br />

0.17<br />

22<br />

22<br />

5.7<br />

5.7<br />

3.1<br />

3.1 -<br />

1.4410<br />

1.4410<br />

S32750<br />

S32750<br />

2507<br />

2507<br />

0.02<br />

0.02<br />

0.27<br />

0.27<br />

25<br />

25 7 4 -<br />

1.4662 S82441 LDX 2404 0.02 0.27 24 3.6 1.6 3Mn<br />

1.4372 201 4372 0.05 0.20 17 4 - 7Mn<br />

1.4301 304 4301 0.04 - 18.1 8.1 -<br />

1.4307 304L 4307 0.02 - 18.1 8.1 - -<br />

1.4541 321 4541 0.04 - 17.3 9.1 - Ti<br />

1.4305 303 4305 0.05 - 17.3 8.2 - S<br />

Austenitic<br />

1.4401 316 4401 0.04 - 17.2 10.1 2.1 -<br />

1.4404 316L 4404 0.02 - 17.2 10.1 2.1 -<br />

1.4571 316Ti 4571 0.04 - 16.8 10.9 2.1 Ti<br />

1.4539 904L 904L 0:01 - 20 25 4.3 1.5Cu<br />

1.4529 N08926 4529 0.01 0.20 20.5 24.8 6.5 Cu<br />

1.4547 S31254 254SMO ® 0.01 0.20 20 18 6.1 Cu<br />

1.4833 309S 4833 0.06 - 22.3 12.6 - -<br />

1.4835 S30815 253MA ® 0.09 0.17 21 11 - 1.6Si, Ce<br />

1.4845 310S 4845 0.05 - 25 20 - -

Total Area: 67.000 sq/m<br />

Covered Area: 32.200 sq/m<br />

Quality<br />

Our Quality Management System is certified accord<strong>in</strong>g to<br />

ISO 9001 Standard.<br />

Safety<br />

Our Safety Management System is certified accord<strong>in</strong>g to<br />

BS OHSAS 18001 Standard.<br />

Environment<br />

Our Environment Management System is certified accord<strong>in</strong>g to<br />

ISO 14001 Standard.<br />

Standards for flat products<br />

EN 10088<br />

EN 10028<br />

ASTM/ASME A/SA 240 - 480<br />

PED 97/23/EC

Our addresses<br />

<strong>Outokumpu</strong> S.p.A.<br />

HEAD OFFICE AND ADMINISTRATIVE HEADQUARTERS: 16121 Genova GE - Piazza Piccapietra, 9<br />

SERVICE CENTRE: 26012 Castelleone CR - Via Fustagno, 21<br />

LOCAL DISTRIBUTION UNIT: 31050 Vascon di Carbonera TV - Via Bortolan, 9/a<br />

OUTOKUMPU S.P.A. Registered address: Via Agnello, 8 - 20121 Milano<br />

Tel +39 010 55431<br />

+39 0374 357311<br />

+39 0422 446855<br />

VAT N. 00718730153<br />

Fax +39 010 5543200<br />

+39 0374 57932<br />

+39 0422 350005

Disclaimer<br />

The <strong>in</strong>formation provided <strong>in</strong> this publication is subject to change without notice. Great attention has been paid<br />

to ensur<strong>in</strong>g that its contents are correct, however <strong>Outokumpu</strong> and its subsidiary companies do not accept<br />

liability for any errors or any <strong>in</strong>formation found to be <strong>in</strong>correct. Any suggestions or descriptions regard<strong>in</strong>g end<br />

uses or applications of the products or process<strong>in</strong>g methods are understood to be provided for <strong>in</strong>formation<br />

only and <strong>Outokumpu</strong> and its affiliated companies do not accept any liability <strong>in</strong> this respect. Customers should<br />

<strong>in</strong>vestigate the suitability of products supplied or manufactured by this company before us<strong>in</strong>g them.<br />

1431EN-GB:1 - ITALIA September April 2010 2011<br />

<strong>Outokumpu</strong> is a global leader <strong>in</strong> the field of sta<strong>in</strong>less steel. Our goal is to be the undisputed number one <strong>in</strong> sta<strong>in</strong>less<br />

steel, bas<strong>in</strong>g our success on operational excellence. Customers <strong>in</strong> a wide range of <strong>in</strong>dustries use our sta<strong>in</strong>less steel and<br />

our services world-wide. Thanks to the fact that sta<strong>in</strong>less steel it can be completely recycled and requires no ma<strong>in</strong>tenance,<br />

and that it is a very tough and durable material, it is one of the keystones to a susta<strong>in</strong>able future.<br />

What makes <strong>Outokumpu</strong> special is its total attention to customers – along the whole way, from R&D right through<br />

to delivery. You have the idea, we offer the best sta<strong>in</strong>less steel <strong>in</strong> the world, the technical know-how and support,<br />

We put your ideas <strong>in</strong>to practice..<br />

www.outokumpu.com