MXA TECH SPEC: HOW FLYWHEEL WEIGHTS WORK

Think of a flywheel weight like a yo-yo. Heavier yo-yos handle better than light ones because of the increased moment of inertia. With more moment of inertia, a yo-yo and a motocross bike accelerate slower, power up with more control and, once in motion, stay in motion. Without any flywheel weight, you couldn’t ride your bike. It would have a short powerband, no thrust and a lot of rev. Before motorcycle manufacturers choose the proper flywheel weight for your bike, they must consider the following factors.

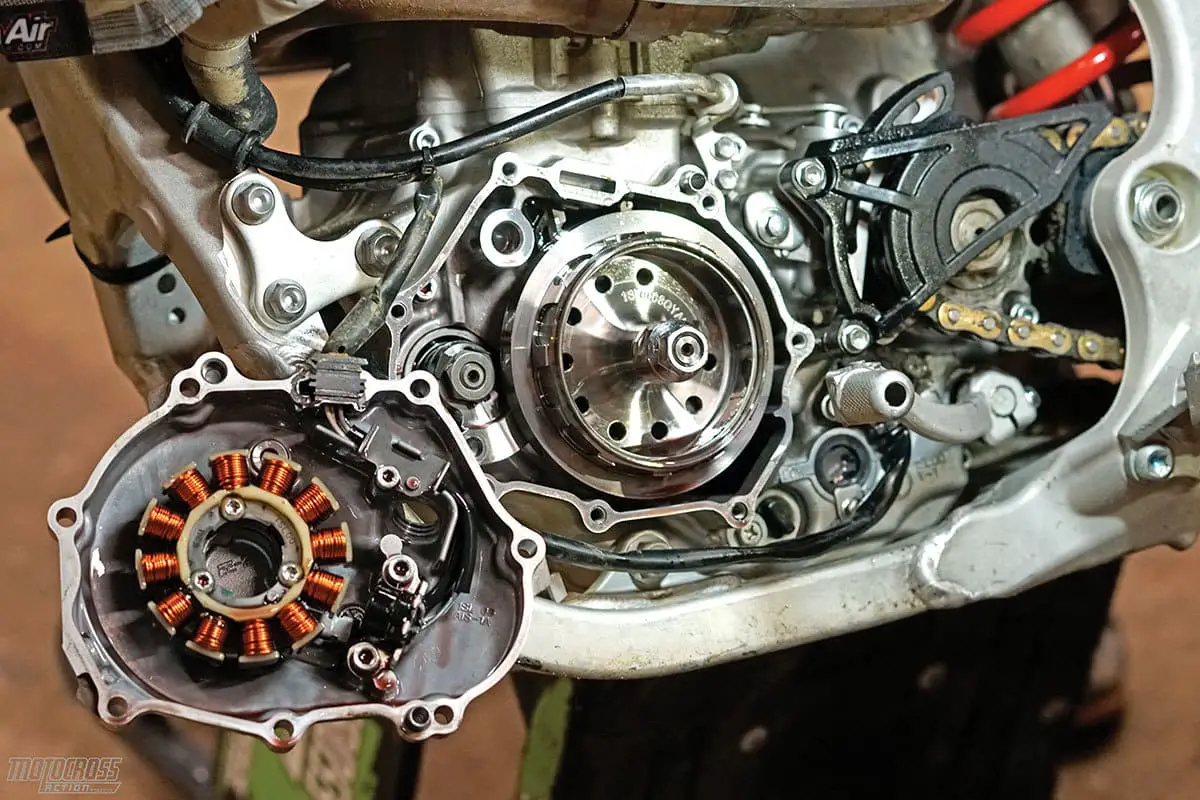

AC current: The size of the flywheel must be large enough to house the magnets that are used to produce engine spark but small enough to make room for the stator windings without creating a bulky engine case.

Engine acceleration: An engine builds speed quicker with a light flywheel and slower with a heavy flywheel.

Inertia: A heavier flywheel carries speed further but is also harder to slow down than a light one.

Flywheel effect: Every rotating component in the engine and chassis creates its own spinning force (clutch basket, gears, chain, wheels, crank, camshaft and piston). The manufacturer needs to pick a flywheel weight that best accommodates all the independent gyroscopic forces inside the motorcycle.

Angular momentum: Believe it or not, too much flywheel weight will make a bike hard to move around or corner.

Intended use: The power characteristics and riding styles used on a 60, 80, 125, 250 or 300 two-stroke and those of 250, 350 or 450 four-strokes all require different flywheel mass; however, just because an engineer selected a given weight doesn’t mean that you can’t be a homegrown engineer and change that weight to suit your needs. History has proven that most factory two-stroke racers, whether on a Yamaha YZ250 or KTM 250SX, used flywheel weights on their works bikes.

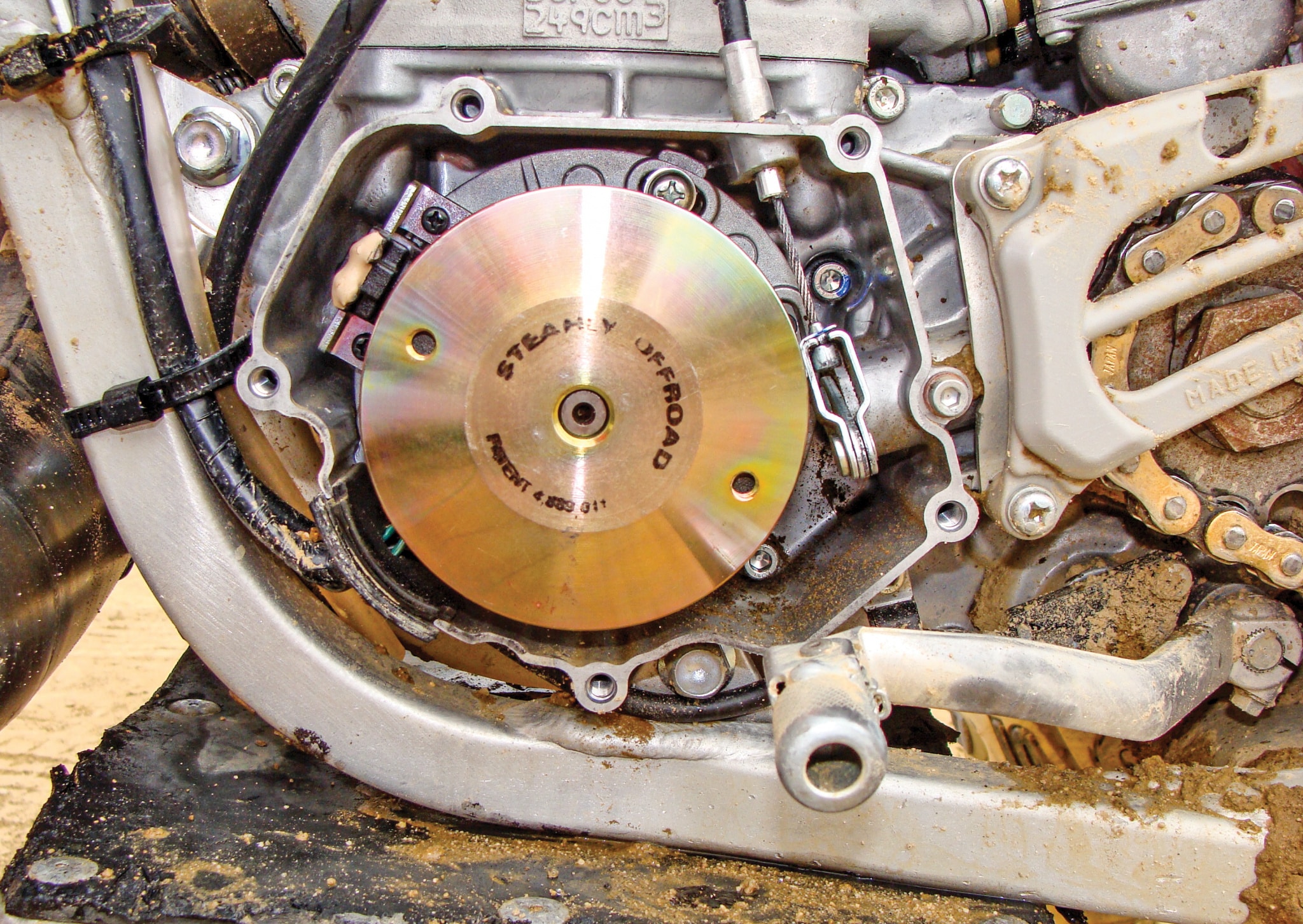

Weight location: Not every 9-ounce flywheel weight has the same effect on an engine. How effectively a flywheel weight works is dependent not only on the weight of the flywheel but where the weight is placed on the flywheel. A 9-ounce flywheel that is 3 inches in diameter will not have as much moment of inertia as a 4-inch-diameter flywheel that weighs the same. For example, older model CRF450s have very small stock flywheels because they do not have enough room in the ignition cover for a big flywheel. MXA felt that adding a 9-ounce flywheel would help the CRF450 get hooked up better, but because of the small ignition rotor, we had to add a 17-ounce flywheel weight to get the same effect as a 9-ounce flywheel on a different bike.

Firing order: A two-stroke uses a lighter flywheel than a four-stroke because it fires every stroke, whereas a four-stroke fires on every other stroke. Two-strokes don’t have to maintain momentum while waiting for the next explosion, thus two-strokes deliver a snappier and more abrupt style of power. With the dominance of modern four-strokes on today’s racetracks, a two-stroke’s rat-a-tat-tat power delivery is often too aggressive for riders bred on slower-revving four-strokes. This is where a flywheel weight comes into play. It can make a two-stroke feel torquier, broader and more hooked up.

Braking: The extra inertia of a heavier flywheel not only resists speeding up, it also resists slowing down. We thought this might be a negative, but the heavier flywheel helped under braking and transitioning through corners. When chopping the throttle with the heavier flywheel, engine rpm doesn’t drop as suddenly. This made for a smoother transition from full speed to full stop, and it reduced the chance of flame-out on touchy four-strokes.

Horsepower: And, while you might be tempted to think that a heavier flywheel would cost your bike horsepower, it is not so. It just makes each gear pull farther, stronger and longer. It is possible that adding a flywheel weight could increase horsepower.

Comments are closed.